CRD LAMIERE is leader in sheet metal processing – iron, steel, inox, aluminum and galvanized sheets. During its twenty years of life the company has kept specializing in steel and inox commercial fittings and furnishing accessories for the large-scale retail trade, as well as for several international furnishing companies working for stores and big shopping centers.

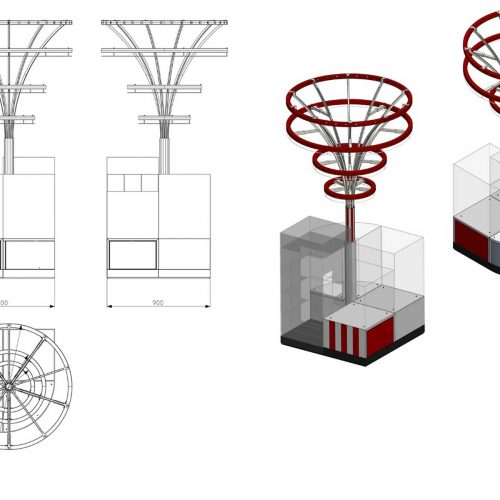

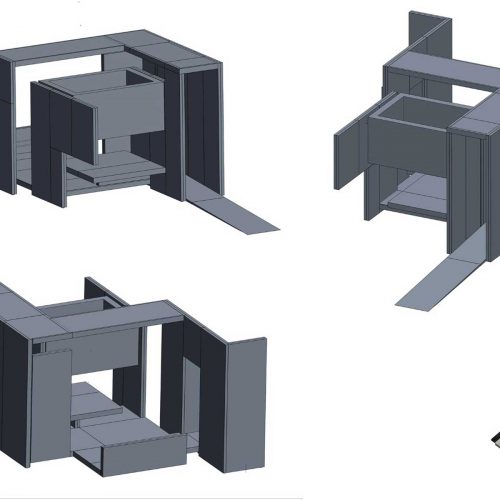

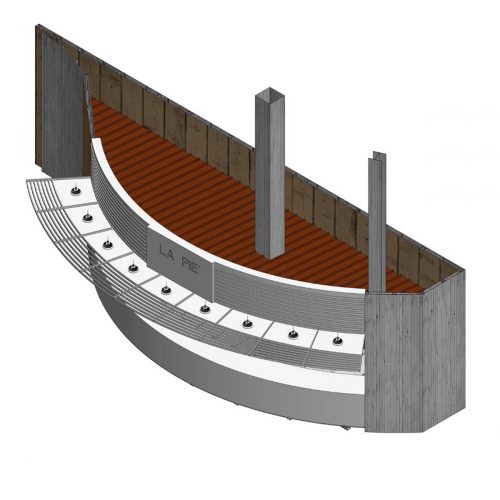

Design

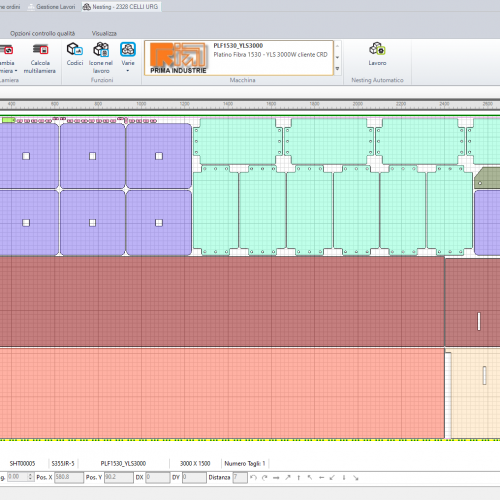

The original idea is carefully developed by the computer technicians of CRD Group by means of an advanced software with 3D modelling and cad-cam system directly integrated with the production sector. Our clients can therefore view the model and confront our highly qualified personnel to make adjustments in order to sort out the best product possible. The proven expertise of our qualified and motivated professionals – designers and mechanical engineers highly skilled in the field of carpentry – combined to the state-of-the-art equipment and to the maximum care to each project makes of the CRD Group a leader in the field of sheet metal processing and a reference point for many other companies around the world. Every single request by clients is cared about with the utmost attention and each step is monitored and controlled by skilled and qualified experts. A great efficiency in consulting and customer care, the timely delivery of goods and the availability to find the right solution in terms of resistance, performance and style, has made CRD Group a highly competitive company as well as a reliable partner. Thanks to a 4000 sq meters of space, CRD Group carries out on its own the production process in all its different phases, granting its clients high quality customized and special-purpose processing. The company’s excellence expresses in particular in the sheet metal processing, thanks to innovative and highly technological numerical control equipment.